Why Transformer Needs Induced Voltage Partial Discharge Tests – IVPD tests

One tailor made AC power supply could satisfy the background condition requirements during transformer partial discharge and induction withstand voltage tests.

Inductive voltage withstand test is a commonly electrical equipment testing method used to evaluate the withstand capability of equipment under high voltage conditions. This testing method is mainly used to detect the electrical equipment, to detect its performance under the over voltage generated by electromagnetic induction to ensure that the device is not damaged or malfunctioned. Partial discharge (PD) in transformers is an electrical phenomenon that occurs within an insulation system. Over time, these discharges will gradually damage the insulation material.

The induced voltage test with the help by AC Power Source verifies the insulation withstand performance of the transformer by introducing an induced voltage higher than the rated voltage of it. By increasing the frequency and maintaining the voltage within a safe value range, the insulation system of the transformer can withstand high voltage in a short period of time. Partial discharge (PD) in transformers is an electrical phenomenon where localized discharges occur within the insulation system. These discharges can gradually damage the insulation material over time, introduce high-frequency voltage (usually 2-3 times of the rated frequency of the equipment) to the device to increase the test voltage, thereby simulating the insulation stress of the equipment under actual working conditions. The test voltage is usually 1.5-2 times of the rated voltage of the equipment, and the duration depends on the specific requirements of the equipment. Partial discharge measurement: While introducing induced voltage, use partial discharge detector instrument to monitor possible partial discharge on transformer.

AC power supply also named as variable frequency power supply, which is very suitable for transformer partial discharge test, and induction withstand voltage test. Partial discharge detection of high-voltage electrical equipment such as transformers, cables, etc. During the testing process, a stable and adjustable power supply is provided to the tested devices, precisely simulating the voltage under different working conditions, effectively triggering potential partial discharge, thereby helping the testing personnel detect insulation defects in a timely manner and ensuring the safe operation of power equipment.

Things needs to prepare for Transformer partial discharge test:

- Multi-meter

- Coupling capacitors

- Cables with copper conductors

- Compensation capacitors, if necessary (because the power factor of the transformer is particularly low, PF about 0.2. In many cases, compensation capacitors need to be added to improve active power)

- Partial discharge detector

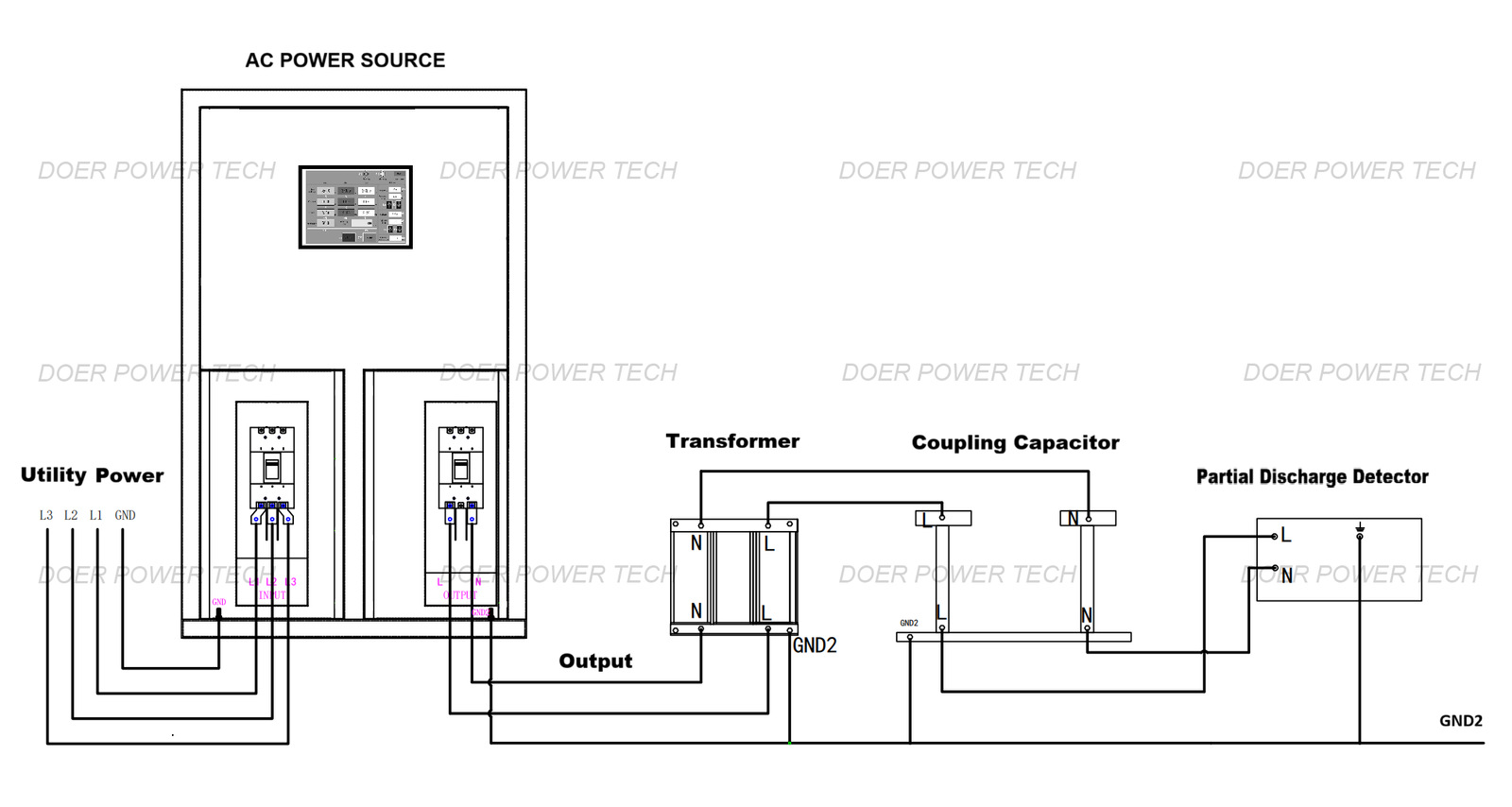

Before testing, it is necessary to use a multi-meter to measure and confirm that the incoming AC power meets what the normal working condition that AC Power Source needs. The incoming power is connected to the input terminal strips, and the output terminal is connected to the AC Power Filter and the transformer. Transformer must be connected to a coupling capacitor, partial discharge detector is really important; This experiment has high requirements for the surrounding environment. Due to the fact that the machines or facilities in factories and laboratories are working around the testing site during the day, the operation of these machines will inevitably interfere with the measurements, it will cause deviation in the value of partial discharge; Therefore, conducting a partial discharge test at night is practical, it provides more accurate data.

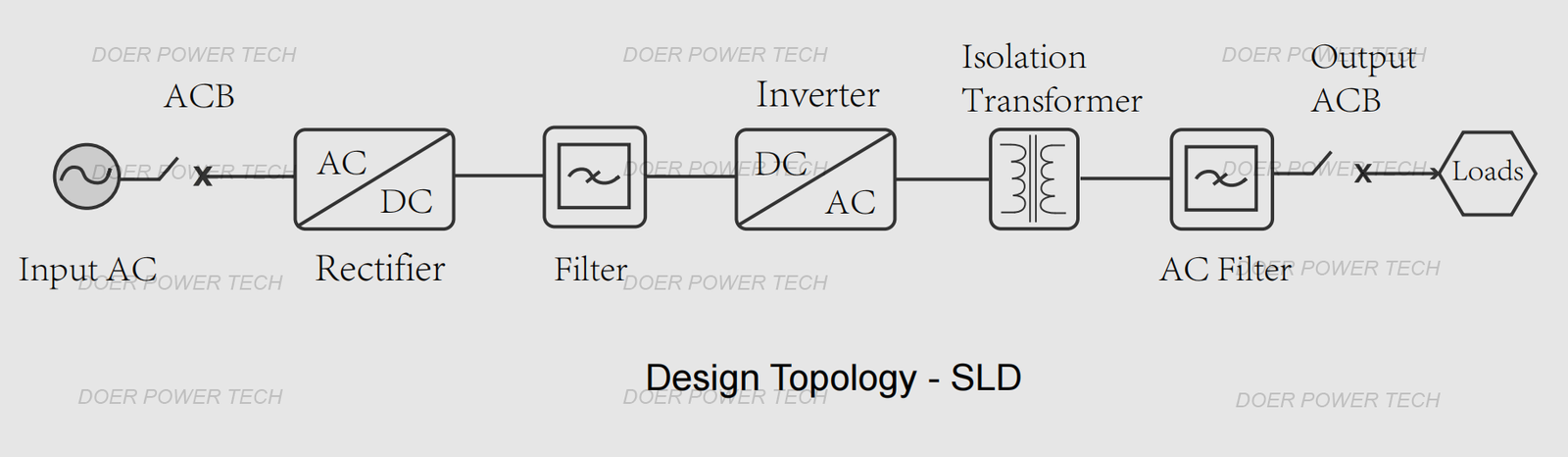

Topology working principle of AC Power Source:

It adopts power electronic frequency conversion technology to meet different experimental requirements by changing the output frequency, thereby changing the frequency of the output AC power. The common output frequency range can varied from 40hz to 500hz, which can flexibly adapt to the testing frequency requirements of various electrical equipment. The variable frequency AC power supply is acquired with an effective filtering system inside. The filtering system can remove high-frequency interference from the output power, which may cause partial discharge. For example, using an LC filter (a filter composed of inductor L and capacitor C), it can filter out interference signals of specific frequencies as needed. By designing the parameters of the filter reasonably, high-frequency interference can be effectively suppressed, thereby reducing the triggering factors of partial discharge.

Our DFC-PDC series AC Power Source is an ideal AC power source for transformer induced voltage and partial discharge tests, The AC source is equipped with an effective filtering system inside. It suffices for the background condition requirement during transformer partial discharge and induced withstand voltage tests. it output variable 40hz hertz to 500 hertz and predetermined volts 1v-1000V, flexibly adapt to the electrical testing requirements, Partial Discharge value less than 4PC max 8PC. under the testing process, a stable and adjustable power supply is provided to the equipment, accurately simulating the voltage under different working conditions, effectively triggering potential partial discharge events, thereby helping to detect insulation defects in a timely manner and ensuring the safe operation of equipment.

Key Benefits: by introducing our new generation AC Power Source, you can achieve:

- Benefit from our cost-effective custom solution engineering.

- Gain a direct line to the factory for technical and pricing advantages.

- Customized Power Converters/Inverters that can be tailored to specific requirements.

Our AC Source could deliver a clean AC power to the experimental equipment. The partial discharge characteristics of insulation materials at different voltages and frequencies are conducted to assist researchers in developing high-performance insulation materials. It was one kind frequency converter for quality inspection to conduct partial discharge tests on newly produced equipment, which ensure the products meet the partial discharge standards at the time of dispatching to customers.

Applications of AC Power Source for Induced voltage & PD tests:

Research experiment: In the research experiment on the performance of electrical insulation materials, this power supply can provide suitable voltage conditions for the experimental samples. By changing parameters such as frequency, the partial discharge characteristics of insulation materials at different voltage frequencies are studied to assist researchers in developing high-performance insulation materials.

High voltage electrical equipment production: In the production of high-voltage electrical equipment, it can serve as a key power source for quality inspection. Conduct no partial discharge tests on newly produced equipment to ensure that the products meet the partial discharge standards at the time of leaving the factory, avoid equipment with partial discharge problems from entering the market, and improve product quality.